Manufacturing Specifications

Integrated Concrete Masonry Units are manufactured in accordance with the requirements of Malaysian Standards MS27-1971 and British Standards BS 2028, 1364-1968

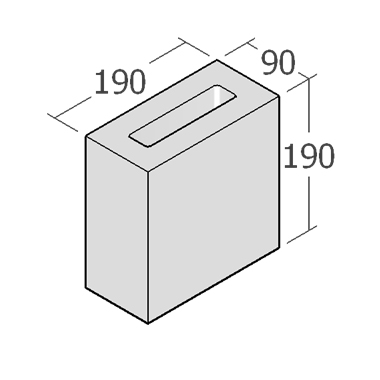

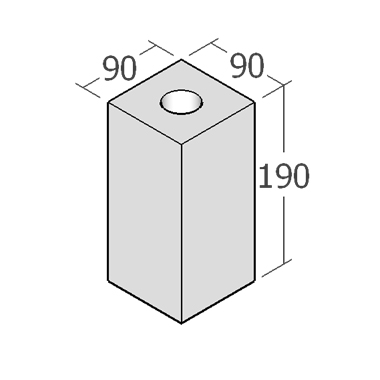

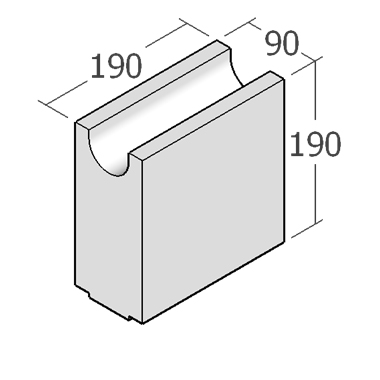

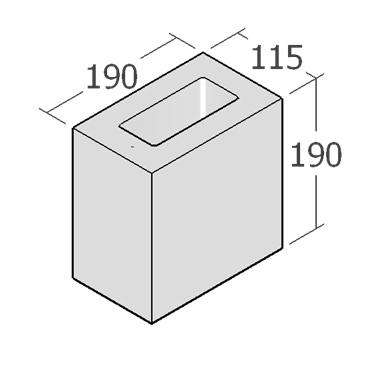

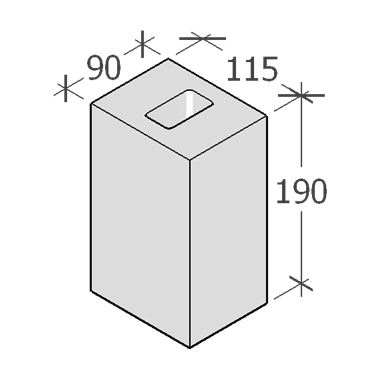

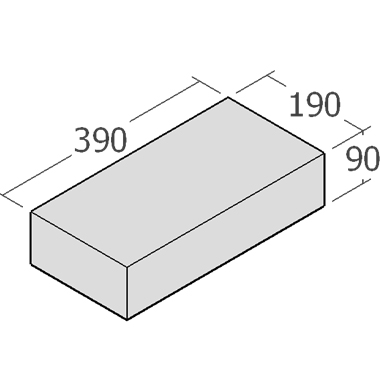

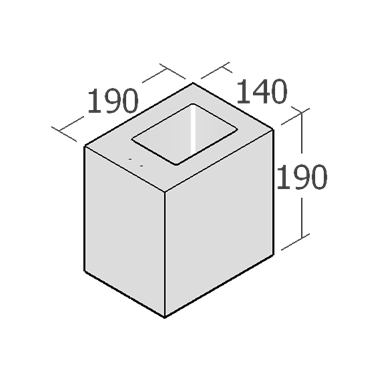

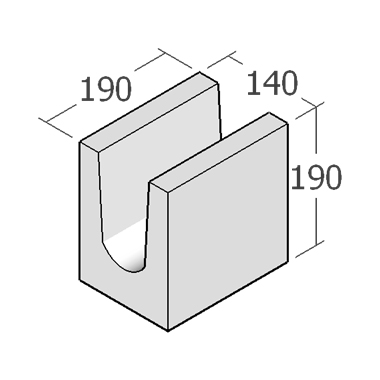

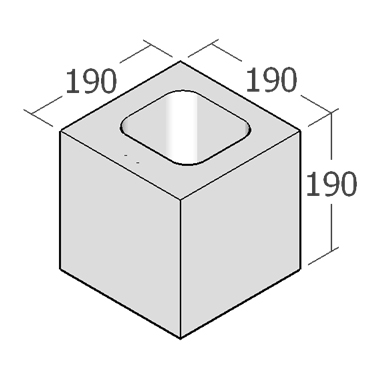

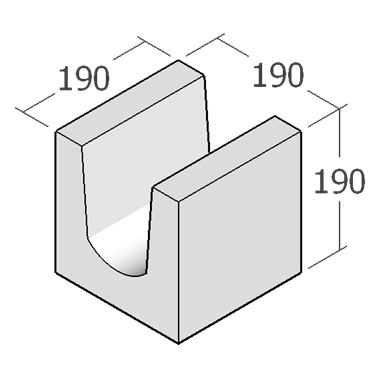

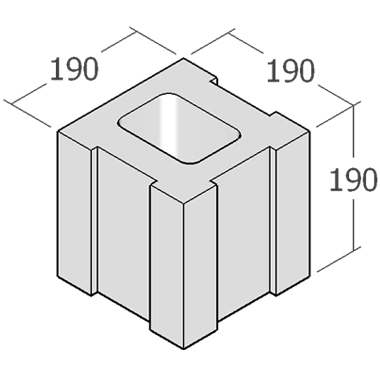

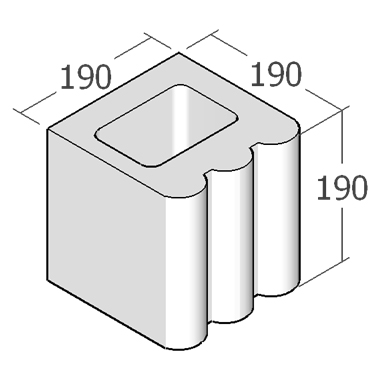

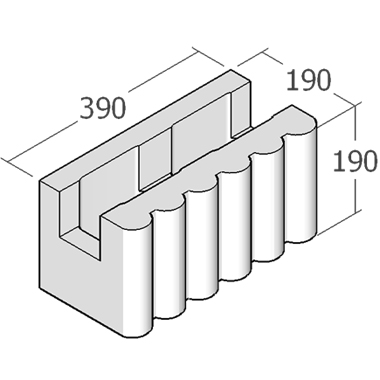

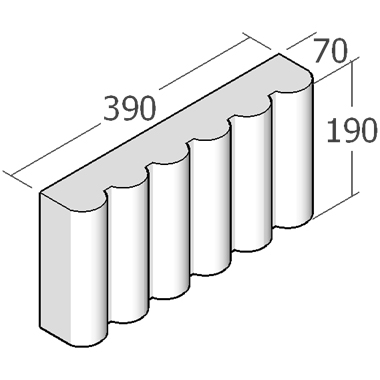

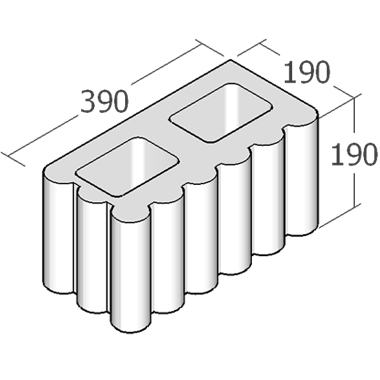

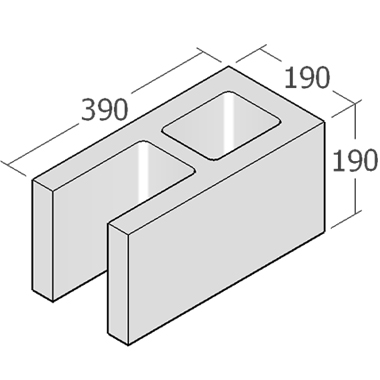

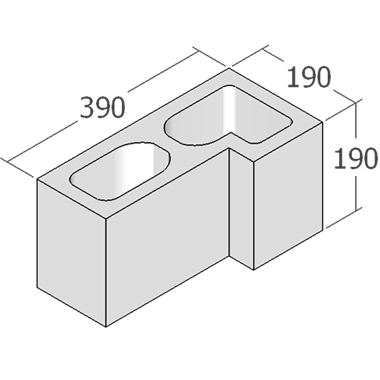

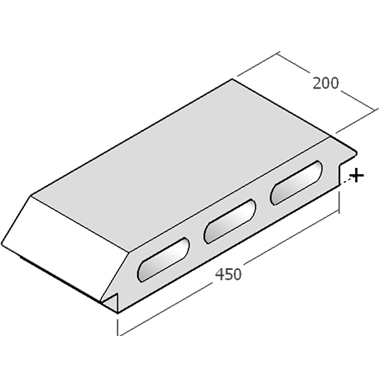

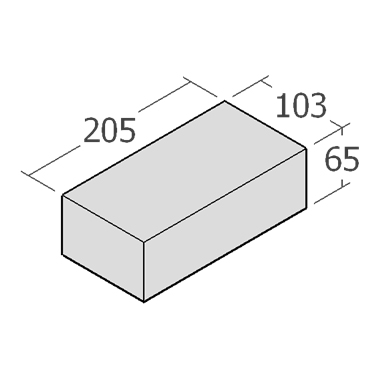

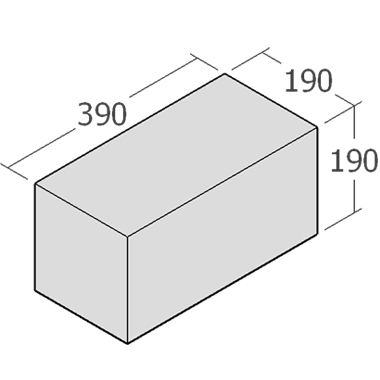

Sizes

Specified manufacturing sizes of blocks allow for 10mm (3/8in) mortar joints and satisfy the concept of a basic size, i.e. the basic space to be occupied by the block and its share of the joints, in accordance with BS 3626, "Recommendations for a System of Tolerances and Fits for Buildings".

Cavities

The total width of cavity in any block, measured at right angles to the face of the blocks as laid in the wall, shall not exceed 65% of the block.The volume of cavity in the block shall exceed 50% of the gross volume of the block.

Density

The gross density of type A blocks whether solid hollow or cellular, shall NOT be less than 1,500 kg/m³ (93.6 lb/ft³). The gross density of type B & C blocks, whether solid, hollow or cellular shall be less than 1,500 kg/m³ (93.6 lb/ft³).

Dimensional Tolerences

No individual measurement of length, height or thickness shall exceed the tolerance of ± 3mm from the specified dimensions.

Drying Shrinkage

Maximum drying shrinkage of block shall not exceed 0.09%.

Wetting Expansion

Maximum wetting expansion of block shall not exceed 0.11%.

Compressive Strength

Average compressive strength based on nett area shall not be less than 1,000 psi, and the strength of the lowest individual block shall not be less than 80% of the average compressive strength. Higher strength blocks can be manufactured on prior special order.

Quality Assurance

The company's modern and well-equipped laboratory carries out rigid daily routine control test on both raw materials and finished products to ensure that they comply with the requirements.